Overview

The Ice Cream & Cultured Innovation Conference is the premier event for makers of ice cream, frozen desserts, yogurt, cottage cheese, sour cream, dips, and spreads, focusing specifically on innovations in research, technology, and emerging market trends across these categories. Attendees will also gain insights into food safety, labeling, and regulations that shape the industry, while engaging in dynamic discussions on technical and practical processing issues.

This conference is a must-attend for those looking to stay ahead of the curve, offering hands-on sessions, product tastings, and unparalleled networking opportunities. Don’t miss the Innovative Flavor and Product Competitions, where the latest in upcoming ice cream flavors, inclusions, novelties and cultured dairy products are celebrated.

Whether you're focused on ice cream or cultured dairy, this conference is designed to inspire and equip professionals with the knowledge and connections needed to drive innovation in their products and processes.

Who Should Attend?

All professionals in ice cream, cultured, frozen dessert technology – including plant managers, regulatory compliance personnel, research and development professionals, and quality assurance staff – will gain new insights, ideas, and solutions by attending the conference. Suppliers to the ice cream and cultured dairy industries are also encouraged to attend.

The 2026 conference will be held from April 14-15 in Naples, FL at the The Ritz-Carlton Naples, Tiburón.

Agenda

*All Times Eastern Print Agenda

| April 14, 2026 | Event | Speaker | Location |

|---|---|---|---|

| 8:00am - 8:30am | Breakfast | Court of Palms | |

| 8:30am - 8:45am |

Welcome Remarks

|

Tiburon Ballroom Salons 2-4 | |

| 8:45am - 9:30am |

Opening General Session - Driving Consumer Interest in Cultured and Frozen Dairy for Health and Wellness

|

Tiburon Ballroom Salons 2-4 | |

|

The global dairy industry is evolving at a rapid pace, with processors responding to consumers’ health and wellness goals and needs. While protein continues to be a big part of the buzz, other nutrients and functional ingredients are gaining traction. There is a lot to learn from countries that are on the cutting-edge of dairy product innovation, including marketing the cultured dairy and frozen desserts that play in the personalized nutrition space. This includes dairy products designed for life stage, day parts and more. With these products, packaging also plays an important role to deliver sufficient doses of beneficial nutrients. And, of course, health and wellness includes little treats and tasty luxuries that feed the mind and bring joy. This session will explore innovations from around the world and how brands are keeping cultured dairy and frozen desserts relevant to today’s curious and mindful consumers. |

|||

| 9:30am - 10:15am |

General Session - The Future of Expertise in Dairy Manufacturing

|

Tiburon Ballroom Salons 2-4 | |

|

The dairy manufacturing industry simultaneously faces a shrinking pool of skilled human operators and rapidly evolving machine capabilities. In this session, we’ll explore a fundamental question — where will expertise truly reside in the factories of the future? With people, or with machines? We’ll dive into the core principles of backward and forward-thinking design philosophies for machines and plants. Should we design based on today’s experience, or should we anticipate the future and build those insights directly into our systems? With the rise of AI, machine learning, and other emerging technologies, the shift toward machine-driven expertise is already becoming a reality. The key lies in how we think about and approach this transformation. Alongside the big-picture concepts, we’ll share practical, easy-to-grasp examples that show how these ideas are already being applied today — offering inspiration and a glimpse into what’s next for modern manufacturing. |

|||

| 10:15am - 10:45am | Networking Break | Tiburon Ballroom Foyer | |

| 10:45am - 11:30am |

Ice Cream Concurrent Session - The Scoop on Color: Navigating Natural Color Conversion in Dairy

|

Tiburon Ballroom Salons 2-4 | |

|

Given the quickly changing regulatory and consumer landscape around colors in the U.S. and around the world, many dairy producers have questions around using natural colors in their products as they prepare to move away from synthetic dyes. In this session, hear expert perspective on some of the common misconceptions around natural colors, and gain insights on natural color options and considerations for use in dairy products. |

|||

| 10:45am - 11:30am |

Yogurt & Cultured Concurrent Session - Unlocking Dairy Excellence: Flexible Ultrafiltration for Superior Greek Yogurt, Cultured Dairy Products & Cream Cheese

|

Tiburon 1 | |

|

Traditional spiral membrane filtration has long been applied in the dairy industry for whey and milk protein concentrate production, and cheese milk fortification. The surge in demand for cultured, concentrated dairy products is driving optimization in production methods. Ultrafiltration using Plate & Frame (UF-P&F) and ceramic membrane technology is redefining what’s possible for Greek yogurt, cream cheese, and other cultured dairy products. This gentle, low-impact membrane process concentrates protein and fat while removing water, minerals, and lactose—delivering a smoother texture, higher yield, whiter appearance and optimal mouthfeel. As protein-rich dairy varieties proliferate on supermarket shelves, UF-P&F and ceramic stand out as the preferred solution for delivering tailored nutrition and superior sensory experiences. Discover how this versatile technology enables you to meet evolving consumer demands while optimizing your process and product portfolio. |

|||

| 11:30am - 12:15pm |

Ice Cream Concurrent Session - Colors Not Included: Reformulating Inclusions in a MAHA World

|

Tiburon Ballroom Salons 2-4 | |

| 11:30am - 12:15pm |

Yogurt & Cultured Concurrent Session - Cracking the Texture Code in Fermented Dairy: A Fusion of Food Science and AI

|

Tiburon 1 | |

|

Developing fermented dairy and alternative dairy products traditionally involves a multifaceted process—ranging from ingredient selection and formulation to processing design, prototype evaluation, data analysis, and strategic business recommendations. This approach demands significant time, resources, and cross-disciplinary expertise. However, the integration of data-driven methodologies and advanced digital tools, combined with deep food science knowledge, is transforming the landscape of product development. These innovations enable faster, more precise optimization of formulations. In this presentation, learn more about the development of fermented dairy and alt-dairy prototypes crafted to achieve targeted texture profile using a data-informed approach. Driven by consumer insights, this session will explore how specific ingredients influence texture characteristics, how these sensory attributes align with consumer expectations, and how strategic formulation can elevate overall product appeal. |

|||

| 12:15pm - 1:15pm | Lunch | Court of Palms | |

| 1:15pm - 2:00pm |

General Session - Meeting Evolving Market and Formulation Demands for Lactose-Free Dairy Ingredients

|

Tiburon Ballroom Salons 2-4 | |

|

The lactose-free (LF) dairy category has experienced rapid growth, evolving well beyond traditional liquid milk to include a broad array of products such as yogurts, frozen desserts, beverages, dips, and snacks. Historically, LF products are primarily produced through direct lactose hydrolysis in liquid dairy formats. However, as consumer demand and application diversity continue to grow, there is an increasing need for dried LF dairy ingredients that offer better shelf life, consistency, and convenience for manufacturers. These ingredients—available in various compositions of fat, protein, and carbohydrates—also provide enhanced formulation flexibility for manufacturers. LF ingredients could present unique technical challenges and application considerations, due to the large presence of monosaccharides. This session will examine the dynamic growth of the LF dairy market, highlight the functional and formulation benefits of dried LF ingredients, and emphasize the value of working with specialized LF ingredient partners to support successful innovation in this expanding category. |

|||

| 2:00pm - 2:45pm | Innovative Cultured Dairy Product Contest | Grand Lawn Pavillion | |

| 2:45pm - 3:30pm |

Ice Cream Concurrent Session - The Packaging Play: A Winning Strategy for Today’s Market Challenges

|

Tiburon Ballroom Salons 2-4 | |

|

Ice cream brands have been playing defense non-stop against consumer, market, and legislative pressures yet expectations to deliver business growth remain. The bad news is the cows aren’t coming home anytime soon. The good news is ice cream brands have an opportunity to flip the script and go on the offensive. Join a panel of sustainability, consumer marketing, R&D and innovation experts to see how brands can leverage packaging to form a winning strategy against key challenges in the ice cream industry. In this session, learn more about how your company can deliver value and transparency to meet consumer expectations, differentiate ice cream brands, address global regulatory pressures, and leverage innovative, design-driven packaging solutions that meet both current and future needs. It's time to turn today’s challenges into tomorrow’s opportunities. |

|||

| 2:45pm - 3:30pm |

Yogurt & Cultured Concurrent Session - Unlock the Future of High-Protein Innovation: Formulating and Processing Ultra-High Protein Yogurts and Dairy Products

|

Tiburon 1 | |

|

This session will present an overview of the leading approaches to producing ultra-high protein yogurts. Attendees will learn how membrane concentration (plate-and-frame ultrafiltration), targeted casein hydrolysis, and protein fortification can be used to produce yogurt with very high protein content without excessively firm texture. Special attention will be given to fortification of milk with microparticulated whey protein, which has become a common method for producing ultra-high protein yogurt. The Center for Dairy Research has developed an alternative approach for fortification which utilizes standard WPC80 that has been screened for protein thermal degradation prior to use. The CDR method allows for lower production costs and can achieve ultra-high protein levels with varying textures based on the proportion of casein and whey proteins used. Attendees will get detailed processing steps and highlight both successes and challenges encountered during development and get technical foundations and practical takeaways for researchers, product developers, and manufacturers exploring the next generation of high-protein dairy. |

|||

| 3:30pm - 4:00am | Networking Break | Grand Lawn Pavillion | |

| 3:30pm - 4:45pm | Innovative Ice Cream Flavor Contest, Part I: Most Innovative Prototype Flavor | Grand Lawn Pavillion | |

| 5:15pm - 6:30pm | Networking Reception | Court of Palms | |

| April 15, 2026 | Event | Speaker | Location |

| 8:00am - 8:30am | Breakfast | Court of Palms | |

| 8:30am - 9:15am |

General Session - Sweetening Production with Smart Tech

|

Tiburon Ballroom Salons 2-4 | |

|

In the world of premium ice cream, consistency, quality, and scalability are key ingredients for success. Chocolate Shoppe Ice Cream, a beloved Wisconsin-based brand, faced the challenge of modernizing its production processes while preserving its artisanal roots. This session explores how the company leveraged a smart manufacturing platform to transform its operations—streamlining inventory management, enhancing traceability, and improving production efficiency. Attendees will gain insights intothe operational hurdles Chocolate Shoppe overcame, how they leveraged real-time data and cloud-based systems for smarter decision-making, the cultural shift within the organization toward digital innovation, and lessons learned and best practices for other food and beverage manufacturers. Whether you're scaling a legacy brand or launching a new product line, this case study offers a flavorful look at how technology can empower growth without compromising quality. |

|||

| 9:15am - 10:00am |

General Session - Environmental Monitoring Programs from An Auditor’s and Lawyer’s Point of View

|

Tiburon Ballroom Salons 2-4 | |

|

In this session, we will delve into the critical intersection of food safety, auditing, and legal compliance. Focusing on environmental monitoring programs, we’ll explore how auditors assess and ensure compliance with food safety standards, with a special emphasis on reviewing root cause investigations. We’ll also discuss how legal perspectives guide companies in navigating regulatory frameworks, managing risks, and responding effectively to audits and regulatory actions. Attendees will gain practical insights into proactive measures, effective communication between auditors, legal teams, and company stakeholders, and how to maintain robust environmental monitor programs. |

|||

| 10:00am - 10:30am | Innovative Ice Cream Flavor Contest, Part II: Most Innovative Flavor and Most Innovative Novelty | Grand Lawn Pavillion | |

| 10:30am - 11:00am | Networking Break | Tiburon Ballroom Foyer | |

| 11:00am - 11:45am |

General Session - Startup Company Showcase

|

Tiburon Ballroom Salons 2-4 | |

| 11:45am - 12:30pm |

Ice Cream Concurrent Session - Cocoa Conundrum: Navigating the Changing World Market for Chocolate

|

Tiburon Ballroom Salons 2-4 | |

| 11:45am - 12:30pm |

Yogurt & Cultured Concurrent Session - Shelf Life Library: What’s the Next Chapter for Natural Preservatives?

|

Tiburon 1 | |

|

The growing demand for “clean label” foods is driven by shifting consumer expectations and evolving regulations. As manufacturers attempt to respond, they are finding it challenging to maintain safety and shelf life while reducing reliance on traditional chemical preservatives. In this presentation, we will briefly review the role and limitations of classic chemical preservatives before exploring emerging natural alternatives. A particular focus will be on cultures with bioprotective effect as a key strategy to control spoilage and foodborne pathogens, with emphasis on cultures targeting yeasts and molds and their mechanisms of action. We will also discuss alternative food preservation approaches and show how natural preservatives can be combined to design robust, sustainable, and consumer-acceptable preservation strategies for the next generation of food products. |

|||

| 12:30pm - 1:30pm | Lunch | Court of Palms | |

| 1:30pm - 2:15pm |

Ice Cream Concurrent Session - Preventing Unwanted Inclusions: Listeria and Ice Cream

|

Tiburon Ballroom Salons 2-4 | |

|

In the last 4 years there have been 8 recalls linked to frozen dairy products. What about the environment is leading to this issue? How do you pressure test your food safety programs and perform a root cause investigation to ensure you are actively seeking and destroying Listeria? In this session, world-renowned expert, Dr. Martin Wiedmann, will take you through these challenges and more to help think through your Listeria control programs. |

|||

| 1:30pm - 2:15pm |

Yogurt & Cultured Concurrent Session - Global Culture: Trends in Fermented Dairy Products from Around the World

|

Tiburon 1 | |

|

What are the next innovative products in the cultured dairy industry in the U.S.? Is it drinkable, stirred, concentrated, or high protein? What is the shape and form? Which functional ingredients are present? This session is aimed at inspiring new development in cultured dairy innovation ingredients by looking into products from the global market. |

|||

| 2:20pm - 3:30pm |

Contest Awards & Closing General Session

|

Tiburon Ballroom Salons 2-4 | |

Opening General Session - Driving Consumer Interest in Cultured and Frozen Dairy for Health and Wellness

The global dairy industry is evolving at a rapid pace, with processors responding to consumers’ health and wellness goals and needs. While protein continues to be a big part of the buzz, other nutrients and functional ingredients are gaining traction. There is a lot to learn from countries that are on the cutting-edge of dairy product innovation, including marketing the cultured dairy and frozen desserts that play in the personalized nutrition space. This includes dairy products designed for life stage, day parts and more. With these products, packaging also plays an important role to deliver sufficient doses of beneficial nutrients. And, of course, health and wellness includes little treats and tasty luxuries that feed the mind and bring joy. This session will explore innovations from around the world and how brands are keeping cultured dairy and frozen desserts relevant to today’s curious and mindful consumers.

Donna Berry

Donna Berry is the owner of Dairy & Food Communications, a company that specializes in business-to-business writing, speaking and consulting projects in the dairy, beverage and food industries. She has a Bachelors Degree in Food Science from the University of Illinois and product development industry experience with Kraft Foods. She has been writing for the dairy trade since 1993; she opened her own business in 2000.

Donna has been tracking consumer behaviors and food trends, with an emphasis on dairy, for 30 years. She currently writes for numerous trade publications, including Food Business News, Dairy Processing, Meat & Poultry, Baking & Snack and Pet Food Processing. Until February 2012, she had been the ingredient technology editor and new products trend tracker for Dairy Foods magazine.

After 18 years on Dairy Foods, she decided it was time to share her knowledge via other publications and media channels. Almost immediately she started her own website, aptly named BerryOnDairy.com, which includes an email newsletter called Daily Dose of Dairy that focuses on innovations in dairy products and related beverages.

Donna is a native of Chicago and still lives in the city. She enjoys exploring the growing foodie scene in The Windy City, as well as while traveling, both domestically and abroad. She makes grocery store visits a priority in every city she visits, which enables her to be an authority on ingredient technology and new product trends.

General Session - The Future of Expertise in Dairy Manufacturing

The dairy manufacturing industry simultaneously faces a shrinking pool of skilled human operators and rapidly evolving machine capabilities. In this session, we’ll explore a fundamental question — where will expertise truly reside in the factories of the future? With people, or with machines? We’ll dive into the core principles of backward and forward-thinking design philosophies for machines and plants. Should we design based on today’s experience, or should we anticipate the future and build those insights directly into our systems?

With the rise of AI, machine learning, and other emerging technologies, the shift toward machine-driven expertise is already becoming a reality. The key lies in how we think about and approach this transformation. Alongside the big-picture concepts, we’ll share practical, easy-to-grasp examples that show how these ideas are already being applied today — offering inspiration and a glimpse into what’s next for modern manufacturing.

Anders Torbensen

Anders Torbensen is an Ice cream equipment professional with more than 20 years of experience in the industry. Educated in mechanical engineering, combined with a passion for the industry, he has been an important factor in recent years technological development of solutions in the global ice cream industry. Strategical focused on the industries challenges of providing solutions, complying with regulations, consumer demands, hygienic and latest carbon impact in the industry, he has a long track record of proven impact in the industry.

Ice Cream Concurrent Session - The Scoop on Color: Navigating Natural Color Conversion in Dairy

Given the quickly changing regulatory and consumer landscape around colors in the U.S. and around the world, many dairy producers have questions around using natural colors in their products as they prepare to move away from synthetic dyes. In this session, hear expert perspective on some of the common misconceptions around natural colors, and gain insights on natural color options and considerations for use in dairy products.

Hannah Kirisits

Hannah Kirisits is a professional within the food and beverage industry, focusing on beverage and dairy applications. She earned her Bachelor of Science in Food Science and Nutrition from the University of Missouri in 2021 and recently completed her Masters in Business Administration at the University of Missouri St. Louis in 2025. Hannah has been at Sensient Food Colors on the Beverage and Dairy Technical Team for over four years. In this role, she works closely with customers to support in the synthetic to natural color conversion as well as creates color solutions to match target hues in new products.

Alexandra Sirosky

Alex Sirosky holds a Master of Food Science & Technology from The Ohio State University, and is a Certified Food Scientist through IFT. She has spent the last decade focused on helping food and beverage companies optimize using natural colors in their applications. Her career spans many industries, including ice cream production, as well as managing R&D within the Beverage & Dairy application space. In her current role, Alex manages part of the commercial strategy for Sensient Food Colors US team and helps problem solve for key customers. She is a passionate foodie and natural color botanical expert who enjoys the challenge of helping companies succeed in their natural color conversions.

Yogurt & Cultured Concurrent Session - Unlocking Dairy Excellence: Flexible Ultrafiltration for Superior Greek Yogurt, Cultured Dairy Products & Cream Cheese

Traditional spiral membrane filtration has long been applied in the dairy industry for whey and milk protein concentrate production, and cheese milk fortification.

The surge in demand for cultured, concentrated dairy products is driving optimization in production methods. Ultrafiltration using Plate & Frame (UF-P&F) and ceramic membrane technology is redefining what’s possible for Greek yogurt, cream cheese, and other cultured dairy products. This gentle, low-impact membrane process concentrates protein and fat while removing water, minerals, and lactose—delivering a smoother texture, higher yield, whiter appearance and optimal mouthfeel.

As protein-rich dairy varieties proliferate on supermarket shelves, UF-P&F and ceramic stand out as the preferred solution for delivering tailored nutrition and superior sensory experiences. Discover how this versatile technology enables you to meet evolving consumer demands while optimizing your process and product portfolio.

Matt Green

Matt Green brings over 25 years of expertise in the dairy industry, specializing in engineering, membrane filtration and plant operations. As Filtration Solutions Manager at Tetra Pak, Matt leads strategic initiatives focused on optimizing plant performance and advancing sustainable processing technologies. He joined Tetra Pak in 2024, following his role as Sales Manager Filtration, where he drove growth through tailored solutions and customer-centric innovation.

Matt’s deep technical knowledge spans water recovery, sustainability, plant effluent treatment, and continuous improvement. His background in R&D and product development has positioned him as a trusted advisor in helping customers meet environmental goals while enhancing operational efficiency.

A graduate of Minnesota State University Moorhead with a Bachelor of Science degree, Matt combines academic rigor with hands-on industry experience. His commitment to sustainability and circular economy principles is reflected in his work to reduce resource consumption and improve waste management across dairy processing facilities.

Matt is passionate about collaborating with partners to deliver filtration solutions that are both economically and environmentally sound. His leadership continues to shape the future of dairy processing through innovation, efficiency and responsible stewardship.

Yogurt & Cultured Concurrent Session - Cracking the Texture Code in Fermented Dairy: A Fusion of Food Science and AI

Developing fermented dairy and alternative dairy products traditionally involves a multifaceted process—ranging from ingredient selection and formulation to processing design, prototype evaluation, data analysis, and strategic business recommendations. This approach demands significant time, resources, and cross-disciplinary expertise.

However, the integration of data-driven methodologies and advanced digital tools, combined with deep food science knowledge, is transforming the landscape of product development. These innovations enable faster, more precise optimization of formulations.

In this presentation, learn more about the development of fermented dairy and alt-dairy prototypes crafted to achieve targeted texture profile using a data-informed approach. Driven by consumer insights, this session will explore how specific ingredients influence texture characteristics, how these sensory attributes align with consumer expectations, and how strategic formulation can elevate overall product appeal.

Bénédicte Coudé

Bénédicte Coudé is a Principal Technologist in Global Dairy Applications with Ingredion Incorporated. She works on the development of innovative dairy & dairy alternative applications with starch-based texturizers, plant-based proteins, and hydrocolloids. Prior to Ingredion, Bénédicte worked for 10 years in the cheese industry: at the Wisconsin Center for Dairy Research where she conducted research and troubleshooting on a wide variety of specialty cheeses and at Schuman Cheese where she specialized in the R&D of Italian type cheeses and development of vegan cheeses. Bénédicte has presented at the American Cheese Society, the International Cheese Symposium, the American Dairy Science Association conference and served as a technical judge at the National and International Cheese Judging Contest, the World Dairy Expo Championship Dairy Product Contest and the American Cheese Society Judging Contest. Bénédicte attended school in France for several years studying Biology and Agronomy and received a BS and MS degree in Agricultural Sciences before transferring to the University of Wisconsin-Madison where she received a MS in Food Science.

David Shaya

David Shaya combines expertise in Food Science and Data Science to drive innovation in predictive formulation. He works across diverse categories: process, analytical chemistry, and product development, leveraging machine learning to accelerate R&D and uncover novel insights. His focus includes applying advanced modeling techniques to optimize formulations and enable data-driven decision-making in sparse datasets.

General Session - Meeting Evolving Market and Formulation Demands for Lactose-Free Dairy Ingredients

The lactose-free (LF) dairy category has experienced rapid growth, evolving well beyond traditional liquid milk to include a broad array of products such as yogurts, frozen desserts, beverages, dips, and snacks. Historically, LF products are primarily produced through direct lactose hydrolysis in liquid dairy formats. However, as consumer demand and application diversity continue to grow, there is an increasing need for dried LF dairy ingredients that offer better shelf life, consistency, and convenience for manufacturers. These ingredients—available in various compositions of fat, protein, and carbohydrates—also provide enhanced formulation flexibility for manufacturers. LF ingredients could present unique technical challenges and application considerations, due to the large presence of monosaccharides. This session will examine the dynamic growth of the LF dairy market, highlight the functional and formulation benefits of dried LF ingredients, and emphasize the value of working with specialized LF ingredient partners to support successful innovation in this expanding category.

Bang Chen

Bang Chen is the Technical Sales Manager at Valio, where he leads business development and provides technical expertise for Valio’s portfolio of specialty lactose-free milk ingredients across the United States. In this role, he works closely with manufacturers in the dairy, beverage, confectionery, and frozen dessert sectors to translate Valio’s advanced ingredient technologies into innovative, commercially viable consumer products.

A food scientist by training and an entrepreneur at heart, Bang specializes in helping B2B partners optimize formulations for taste, nutrition, and functional performance, enabling them to bring the next generation of high-protein, sugar-reduced, lactose-free, and functional CPGs to market.

Before joining Valio, Bang spent 9 years at Saputo’s dairy ingredients business, where he held roles spanning operations, R&D, and commercial functions.

Bang holds a Master of Science degree in Food Science from the University of Wisconsin–Madison and currently resides in Madison, Wisconsin.

Ice Cream Concurrent Session - The Packaging Play: A Winning Strategy for Today’s Market Challenges

Ice cream brands have been playing defense non-stop against consumer, market, and legislative pressures yet expectations to deliver business growth remain.

The bad news is the cows aren’t coming home anytime soon. The good news is ice cream brands have an opportunity to flip the script and go on the offensive.

Join a panel of sustainability, consumer marketing, R&D and innovation experts to see how brands can leverage packaging to form a winning strategy against key challenges in the ice cream industry. In this session, learn more about how your company can deliver value and transparency to meet consumer expectations, differentiate ice cream brands, address global regulatory pressures, and leverage innovative, design-driven packaging solutions that meet both current and future needs.

It's time to turn today’s challenges into tomorrow’s opportunities.

Diane Marret

Diane leads a dedicated team focused on advancing the development of packaging that is fully recyclable, reusable, or compostable—leveraging cutting-edge materials and sustainable design. Diane is a passionate advocate for programs that improve waste infrastructure, enhance consumer education, and promote collaborative problem-solving. She also actively engages in policy development and advocacy to support scalable, systemic change across the packaging value chain. Before joining Amcor, Diane built a strong foundation in engineering and program management through roles in the home appliance and automotive industries. Her cross-sector experience fuels her strategic approach to driving impactful, scalable sustainability initiatives.

Jordan French

Jordan is responsible for industrial design, UX research, and design strategy at Berry Global’s in-house design team, Blue Clover Studios. He is the listed inventor on 20 patents and has over 15 years of industry experience working with global brands across the CPG spectrum in food & beverage, personal care, home care, healthcare, food service, and industrial markets.

Andrew Dick

Andrew is a seasoned marketing and sales leader with a proven track record in driving product innovation, brand growth, and strategic market expansion. With experience spanning Europe, North America, Asia, and Latin America, Andrew has successfully led global product launches and redefined strategies for top CPG brands. In his current role as Director of Marketing and Strategic Product Development at Amcor, he collaborates with brands to transform consumer insights into innovative, market-ready packaging solutions that drive value and differentiation.

Yogurt & Cultured Concurrent Session - Unlock the Future of High-Protein Innovation: Formulating and Processing Ultra-High Protein Yogurts and Dairy Products

This session will present an overview of the leading approaches to producing ultra-high protein yogurts. Attendees will learn how membrane concentration (plate-and-frame ultrafiltration), targeted casein hydrolysis, and protein fortification can be used to produce yogurt with very high protein content without excessively firm texture. Special attention will be given to fortification of milk with microparticulated whey protein, which has become a common method for producing ultra-high protein yogurt. The Center for Dairy Research has developed an alternative approach for fortification which utilizes standard WPC80 that has been screened for protein thermal degradation prior to use. The CDR method allows for lower production costs and can achieve ultra-high protein levels with varying textures based on the proportion of casein and whey proteins used.

Attendees will get detailed processing steps and highlight both successes and challenges encountered during development and get technical foundations and practical takeaways for researchers, product developers, and manufacturers exploring the next generation of high-protein dairy.

Daniel Wilbanks, PhD

Daniel is the lead coordinator for the Dairy Products and Processing Technologies group at the Center for Dairy Research at the University of Wisconsin – Madison. Before joining CDR, Daniel worked as an analytical chemist developing methods for the infant formula industry prior to earning a PhD at the University of Wisconsin – Madison in Food Science where he investigated the use of membrane filtration to develop novel dairy products for use in beverages and high protein yogurts.

General Session - Sweetening Production with Smart Tech

In the world of premium ice cream, consistency, quality, and scalability are key ingredients for success. Chocolate Shoppe Ice Cream, a beloved Wisconsin-based brand, faced the challenge of modernizing its production processes while preserving its artisanal roots. This session explores how the company leveraged a smart manufacturing platform to transform its operations—streamlining inventory management, enhancing traceability, and improving production efficiency. Attendees will gain insights intothe operational hurdles Chocolate Shoppe overcame, how they leveraged real-time data and cloud-based systems for smarter decision-making, the cultural shift within the organization toward digital innovation, and lessons learned and best practices for other food and beverage manufacturers. Whether you're scaling a legacy brand or launching a new product line, this case study offers a flavorful look at how technology can empower growth without compromising quality.

Michael Hart

Michael Hart is the Head of Product, Industry Strategy & Growth at Rockwell Automation, driving long-term growth for Rockwell’s MES portfolio across key verticals, including Automotive, F&B, and Life Sciences. With nearly 30 years of experience in the cloud software industry, he has a deep understanding of software needs for the manufacturing industry. His background also includes general management, product management, product development, marketing and strategy.

Sarah Deadman

Since joining Chocolate Shoppe Ice Cream in 2005, Sarah Deadman has played a key role in shaping the company’s growth and success. As COO, she focuses on strategic planning, operations, supply chain management, and co-manufacturing partnerships—helping the business grow efficiently while staying true to its values and handcrafted roots.

General Session - Environmental Monitoring Programs from An Auditor’s and Lawyer’s Point of View

In this session, we will delve into the critical intersection of food safety, auditing, and legal compliance. Focusing on environmental monitoring programs, we’ll explore how auditors assess and ensure compliance with food safety standards, with a special emphasis on reviewing root cause investigations. We’ll also discuss how legal perspectives guide companies in navigating regulatory frameworks, managing risks, and responding effectively to audits and regulatory actions. Attendees will gain practical insights into proactive measures, effective communication between auditors, legal teams, and company stakeholders, and how to maintain robust environmental monitor programs.

Kimberly Bukowski

Kimberly Bukowski provides leadership for the Dairy Foods Certificate Program and Workforce Development, including program oversight, marketing, and development. Kim also provides Global Food Safety Initiative (GFSI) consulting and training to the industry. She is a certified Safe Quality Foods (SQF) Auditor and Trainer. She is a lead instructor for FSPCA Preventive Controls and FSVP. Kim’s career in the dairy food industry includes working in dairy quality and processing, plant management, brand development, and building a facility to manufacture and sell ice cream. She managed the Borden’s Ice Cream Plant, the Cornell Dairy Plant, Kimberly’s Ice Cream and has performed 3rd party audits in over 150 plants in the US.

Melanie Neumann

Melanie Neumann is the principal attorney and founder of NAS. Ms. Neumann has invested over 25 years in providing the food and beverage industry with actionable and practical legal and regulatory insights through the lens of enterprise risk management. Topics include without limit: food laws and regulatory compliance, advertising and labeling compliance, intellectual property, corporate contracting, data management, pre-and post-acquisition due diligence, supplier and co-manufacturing contracting and risk assessment, recall and incident management, and other operational and brand reputation risk management solutions.

NAS interacts with various stakeholders on behalf of her clients –from production line operators to CEO’s and CFO’s, regulators to academics, the CDC, and the media--in response to outbreaks, recalls, inspection findings, enforcement actions, complaint management, and alleged illness claims to help resolve incidents by facilitating robust root cause analyses and helping companies identify appropriate corrective actions and other risk mitigations to protect public health and business reputation.

Ms. Neumann is also a professional coach who works with food safety professionals in various stages of their careers helping them to increase effectiveness and impact. She is a thought leader and sought after speaker and author on various topics she specializes in.

Melanie held corporate, food law and food safety positions with leading companies such as Hormel Foods, the Schwan Food Company, Price-Waterhouse Coopers, The Acheson Group, and companies she has launched and sold, and is now leading Neumann Advisory Services, LLC.

Melanie is a graduate of Mitchell-Hamline Law School in St. Paul, MN with a juris doctorate in law degree, and Michigan State University with a Masters of Science in Food Safety. She serves as an adjunct professor at her law school alma mater.

In her spare time, Melanie is a competitive triathlete competing in numerous IRONMAN® full-distance triathlons, including the IRONMAN® World Championships.

Yogurt & Cultured Concurrent Session - Shelf Life Library: What’s the Next Chapter for Natural Preservatives?

The growing demand for “clean label” foods is driven by shifting consumer expectations and evolving regulations. As manufacturers attempt to respond, they are finding it challenging to maintain safety and shelf life while reducing reliance on traditional chemical preservatives. In this presentation, we will briefly review the role and limitations of classic chemical preservatives before exploring emerging natural alternatives. A particular focus will be on cultures with bioprotective effect as a key strategy to control spoilage and foodborne pathogens, with emphasis on cultures targeting yeasts and molds and their mechanisms of action. We will also discuss alternative food preservation approaches and show how natural preservatives can be combined to design robust, sustainable, and consumer-acceptable preservation strategies for the next generation of food products.

Sophia Harrand, PhD

Sophia Harrand is a Senior Application Scientist in Dairy Bioprotection at Novonesis in Denmark. She designs and optimizes cultures that extend shelf life and protect against spoilage and foodborne pathogens, helping customers balance safety, quality, and clean label expectations. She holds a PhD in Food Science from Cornell University, where she studied foodborne pathogens, especially Listeria. Sophia is particularly interested in translating scientific insights into practical, sustainable preservation solutions that enhance food safety and quality.

Ice Cream Concurrent Session - Preventing Unwanted Inclusions: Listeria and Ice Cream

In the last 4 years there have been 8 recalls linked to frozen dairy products. What about the environment is leading to this issue? How do you pressure test your food safety programs and perform a root cause investigation to ensure you are actively seeking and destroying Listeria? In this session, world-renowned expert, Dr. Martin Wiedmann, will take you through these challenges and more to help think through your Listeria control programs.

Martin Wiedmann, DVM, PhD

Martin Wiedmann, Dr. med. vet, Ph.D. is the Gellert Family Professor of Food Safety at Cornell University. Martin received a veterinary degree and a doctorate in Veterinary Medicine from the Ludwig-Maximilians University in Munich, and a Ph.D. in Food Science from Cornell. His research interests focus on farm-to-table microbial food quality and food safety and the application of molecular tools and quantitative and modelling approaches to study the transmission of foodborne pathogens and spoilage organisms. He is particularly well known for his work on Listeria transmission. He and his team are regularly asked to help industry across the world with a range of microbial food safety and quality challenges. He is a fellow of the American Association for the Advancement of Science (AAAS), the Institute of Food Technologists (IFT), the American Academy of Microbiology (AAM), and the International Academy of Food Science and Technology.

Yogurt & Cultured Concurrent Session - Global Culture: Trends in Fermented Dairy Products from Around the World

What are the next innovative products in the cultured dairy industry in the U.S.? Is it drinkable, stirred, concentrated, or high protein? What is the shape and form? Which functional ingredients are present?

This session is aimed at inspiring new development in cultured dairy innovation ingredients by looking into products from the global market.

Andrew Sztehlo

Andrew Sztehlo is Chief R&D Officer at Ferrero Ice Cream, having previously held the same role at Unilever. In his 41st year in the ice cream industry, with a 1st class degree in Chemistry and professionally as a product developer and project manager. He was lived/worked in Europe, Asia, Australasia and the US. Based in Luxembourg, he is also the chair of the European Ice Cream trade association, Euroglaces. His favourite ice cream is a Klondike bar. WWYDFAKB.

Speakers

Donna Berry

Food Scientist, Editor and Consultant | Daily Dose of Dairy

Donna Berry

Donna Berry is the owner of Dairy & Food Communications, a company that specializes in business-to-business writing, speaking and consulting projects in the dairy, beverage and food industries. She has a Bachelors Degree in Food Science from the University of Illinois and product development industry experience with Kraft Foods. She has been writing for the dairy trade since 1993; she opened her own business in 2000.

Donna has been tracking consumer behaviors and food trends, with an emphasis on dairy, for 30 years. She currently writes for numerous trade publications, including Food Business News, Dairy Processing, Meat & Poultry, Baking & Snack and Pet Food Processing. Until February 2012, she had been the ingredient technology editor and new products trend tracker for Dairy Foods magazine.

After 18 years on Dairy Foods, she decided it was time to share her knowledge via other publications and media channels. Almost immediately she started her own website, aptly named BerryOnDairy.com, which includes an email newsletter called Daily Dose of Dairy that focuses on innovations in dairy products and related beverages.

Donna is a native of Chicago and still lives in the city. She enjoys exploring the growing foodie scene in The Windy City, as well as while traveling, both domestically and abroad. She makes grocery store visits a priority in every city she visits, which enables her to be an authority on ingredient technology and new product trends.

Kimberly Bukowski

Extension Support Specialist, Dairy Foods Extension | Cornell University College of Agriculture and Life Sciences

Kimberly Bukowski

Kimberly Bukowski provides leadership for the Dairy Foods Certificate Program and Workforce Development, including program oversight, marketing, and development. Kim also provides Global Food Safety Initiative (GFSI) consulting and training to the industry. She is a certified Safe Quality Foods (SQF) Auditor and Trainer. She is a lead instructor for FSPCA Preventive Controls and FSVP. Kim’s career in the dairy food industry includes working in dairy quality and processing, plant management, brand development, and building a facility to manufacture and sell ice cream. She managed the Borden’s Ice Cream Plant, the Cornell Dairy Plant, Kimberly’s Ice Cream and has performed 3rd party audits in over 150 plants in the US.

Bang Chen

Technical Sales Manager | Valio USA

Bang Chen

Bang Chen is the Technical Sales Manager at Valio, where he leads business development and provides technical expertise for Valio’s portfolio of specialty lactose-free milk ingredients across the United States. In this role, he works closely with manufacturers in the dairy, beverage, confectionery, and frozen dessert sectors to translate Valio’s advanced ingredient technologies into innovative, commercially viable consumer products.

A food scientist by training and an entrepreneur at heart, Bang specializes in helping B2B partners optimize formulations for taste, nutrition, and functional performance, enabling them to bring the next generation of high-protein, sugar-reduced, lactose-free, and functional CPGs to market.

Before joining Valio, Bang spent 9 years at Saputo’s dairy ingredients business, where he held roles spanning operations, R&D, and commercial functions.

Bang holds a Master of Science degree in Food Science from the University of Wisconsin–Madison and currently resides in Madison, Wisconsin.

Bénédicte Coudé

Senior Associate, Gobal Dairy & Dairy Alternative Applications | Ingredion

Bénédicte Coudé

Bénédicte Coudé is a Principal Technologist in Global Dairy Applications with Ingredion Incorporated. She works on the development of innovative dairy & dairy alternative applications with starch-based texturizers, plant-based proteins, and hydrocolloids. Prior to Ingredion, Bénédicte worked for 10 years in the cheese industry: at the Wisconsin Center for Dairy Research where she conducted research and troubleshooting on a wide variety of specialty cheeses and at Schuman Cheese where she specialized in the R&D of Italian type cheeses and development of vegan cheeses. Bénédicte has presented at the American Cheese Society, the International Cheese Symposium, the American Dairy Science Association conference and served as a technical judge at the National and International Cheese Judging Contest, the World Dairy Expo Championship Dairy Product Contest and the American Cheese Society Judging Contest. Bénédicte attended school in France for several years studying Biology and Agronomy and received a BS and MS degree in Agricultural Sciences before transferring to the University of Wisconsin-Madison where she received a MS in Food Science.

Sarah Deadman

Chief Operating Officer | Chocolate Shoppe Ice Cream Company

Sarah Deadman

Since joining Chocolate Shoppe Ice Cream in 2005, Sarah Deadman has played a key role in shaping the company’s growth and success. As COO, she focuses on strategic planning, operations, supply chain management, and co-manufacturing partnerships—helping the business grow efficiently while staying true to its values and handcrafted roots.

Andrew Dick

Director of Marketing and Strategic Product Development | Amcor

Andrew Dick

Andrew is a seasoned marketing and sales leader with a proven track record in driving product innovation, brand growth, and strategic market expansion. With experience spanning Europe, North America, Asia, and Latin America, Andrew has successfully led global product launches and redefined strategies for top CPG brands. In his current role as Director of Marketing and Strategic Product Development at Amcor, he collaborates with brands to transform consumer insights into innovative, market-ready packaging solutions that drive value and differentiation.

Jordan French

Sr. Design Manager | Amcor

Jordan French

Jordan is responsible for industrial design, UX research, and design strategy at Berry Global’s in-house design team, Blue Clover Studios. He is the listed inventor on 20 patents and has over 15 years of industry experience working with global brands across the CPG spectrum in food & beverage, personal care, home care, healthcare, food service, and industrial markets.

Matt Green

Business Development Manager | Tetra Pak

Matt Green

Matt Green brings over 25 years of expertise in the dairy industry, specializing in engineering, membrane filtration and plant operations. As Filtration Solutions Manager at Tetra Pak, Matt leads strategic initiatives focused on optimizing plant performance and advancing sustainable processing technologies. He joined Tetra Pak in 2024, following his role as Sales Manager Filtration, where he drove growth through tailored solutions and customer-centric innovation.

Matt’s deep technical knowledge spans water recovery, sustainability, plant effluent treatment, and continuous improvement. His background in R&D and product development has positioned him as a trusted advisor in helping customers meet environmental goals while enhancing operational efficiency.

A graduate of Minnesota State University Moorhead with a Bachelor of Science degree, Matt combines academic rigor with hands-on industry experience. His commitment to sustainability and circular economy principles is reflected in his work to reduce resource consumption and improve waste management across dairy processing facilities.

Matt is passionate about collaborating with partners to deliver filtration solutions that are both economically and environmentally sound. His leadership continues to shape the future of dairy processing through innovation, efficiency and responsible stewardship.

Michael Hart

Head of Product - Industry Strategy & Growth | Rockwell Automation

Michael Hart

Michael Hart is the Head of Product, Industry Strategy & Growth at Rockwell Automation, driving long-term growth for Rockwell’s MES portfolio across key verticals, including Automotive, F&B, and Life Sciences. With nearly 30 years of experience in the cloud software industry, he has a deep understanding of software needs for the manufacturing industry. His background also includes general management, product management, product development, marketing and strategy.

Hannah Kirisits

Application Scientist III | Sensient

Hannah Kirisits

Hannah Kirisits is a professional within the food and beverage industry, focusing on beverage and dairy applications. She earned her Bachelor of Science in Food Science and Nutrition from the University of Missouri in 2021 and recently completed her Masters in Business Administration at the University of Missouri St. Louis in 2025. Hannah has been at Sensient Food Colors on the Beverage and Dairy Technical Team for over four years. In this role, she works closely with customers to support in the synthetic to natural color conversion as well as creates color solutions to match target hues in new products.

Diane Marret

Sr. Director of Sustainability | Amcor

Diane Marret

Diane leads a dedicated team focused on advancing the development of packaging that is fully recyclable, reusable, or compostable—leveraging cutting-edge materials and sustainable design. Diane is a passionate advocate for programs that improve waste infrastructure, enhance consumer education, and promote collaborative problem-solving. She also actively engages in policy development and advocacy to support scalable, systemic change across the packaging value chain. Before joining Amcor, Diane built a strong foundation in engineering and program management through roles in the home appliance and automotive industries. Her cross-sector experience fuels her strategic approach to driving impactful, scalable sustainability initiatives.

Melanie Neumann

Founder | Neumann Advisory Services

Melanie Neumann

Melanie Neumann is the principal attorney and founder of NAS. Ms. Neumann has invested over 25 years in providing the food and beverage industry with actionable and practical legal and regulatory insights through the lens of enterprise risk management. Topics include without limit: food laws and regulatory compliance, advertising and labeling compliance, intellectual property, corporate contracting, data management, pre-and post-acquisition due diligence, supplier and co-manufacturing contracting and risk assessment, recall and incident management, and other operational and brand reputation risk management solutions.

NAS interacts with various stakeholders on behalf of her clients –from production line operators to CEO’s and CFO’s, regulators to academics, the CDC, and the media--in response to outbreaks, recalls, inspection findings, enforcement actions, complaint management, and alleged illness claims to help resolve incidents by facilitating robust root cause analyses and helping companies identify appropriate corrective actions and other risk mitigations to protect public health and business reputation.

Ms. Neumann is also a professional coach who works with food safety professionals in various stages of their careers helping them to increase effectiveness and impact. She is a thought leader and sought after speaker and author on various topics she specializes in.

Melanie held corporate, food law and food safety positions with leading companies such as Hormel Foods, the Schwan Food Company, Price-Waterhouse Coopers, The Acheson Group, and companies she has launched and sold, and is now leading Neumann Advisory Services, LLC.

Melanie is a graduate of Mitchell-Hamline Law School in St. Paul, MN with a juris doctorate in law degree, and Michigan State University with a Masters of Science in Food Safety. She serves as an adjunct professor at her law school alma mater.

In her spare time, Melanie is a competitive triathlete competing in numerous IRONMAN® full-distance triathlons, including the IRONMAN® World Championships.

David Shaya

Associate – Predictive Formulation | Ingredion

David Shaya

David Shaya combines expertise in Food Science and Data Science to drive innovation in predictive formulation. He works across diverse categories: process, analytical chemistry, and product development, leveraging machine learning to accelerate R&D and uncover novel insights. His focus includes applying advanced modeling techniques to optimize formulations and enable data-driven decision-making in sparse datasets.

Alexandra Sirosky

Global Sales Manager | Sensient

Alexandra Sirosky

Alex Sirosky holds a Master of Food Science & Technology from The Ohio State University, and is a Certified Food Scientist through IFT. She has spent the last decade focused on helping food and beverage companies optimize using natural colors in their applications. Her career spans many industries, including ice cream production, as well as managing R&D within the Beverage & Dairy application space. In her current role, Alex manages part of the commercial strategy for Sensient Food Colors US team and helps problem solve for key customers. She is a passionate foodie and natural color botanical expert who enjoys the challenge of helping companies succeed in their natural color conversions.

Andrew Sztehlo

Chief R&D Officer | Ferrero Ice Cream

Andrew Sztehlo

Andrew Sztehlo is Chief R&D Officer at Ferrero Ice Cream, having previously held the same role at Unilever. In his 41st year in the ice cream industry, with a 1st class degree in Chemistry and professionally as a product developer and project manager. He was lived/worked in Europe, Asia, Australasia and the US. Based in Luxembourg, he is also the chair of the European Ice Cream trade association, Euroglaces. His favourite ice cream is a Klondike bar. WWYDFAKB.

Anders Torbensen

VP Sales & Marketing, Gram Equipment

Anders Torbensen

Anders Torbensen is an Ice cream equipment professional with more than 20 years of experience in the industry. Educated in mechanical engineering, combined with a passion for the industry, he has been an important factor in recent years technological development of solutions in the global ice cream industry. Strategical focused on the industries challenges of providing solutions, complying with regulations, consumer demands, hygienic and latest carbon impact in the industry, he has a long track record of proven impact in the industry.

Martin Wiedmann, DVM, PhD

Gellert Family Professor in Food Safety, Food Science | Cornell University College of Agriculture and Life Sciences

Martin Wiedmann, DVM, PhD

Martin Wiedmann, Dr. med. vet, Ph.D. is the Gellert Family Professor of Food Safety at Cornell University. Martin received a veterinary degree and a doctorate in Veterinary Medicine from the Ludwig-Maximilians University in Munich, and a Ph.D. in Food Science from Cornell. His research interests focus on farm-to-table microbial food quality and food safety and the application of molecular tools and quantitative and modelling approaches to study the transmission of foodborne pathogens and spoilage organisms. He is particularly well known for his work on Listeria transmission. He and his team are regularly asked to help industry across the world with a range of microbial food safety and quality challenges. He is a fellow of the American Association for the Advancement of Science (AAAS), the Institute of Food Technologists (IFT), the American Academy of Microbiology (AAM), and the International Academy of Food Science and Technology.

Daniel Wilbanks, PhD

Project Coordinator - Cultured Milk and Processing, Center for Dairy Research | University of Wisconsin - Madison

Daniel Wilbanks, PhD

Daniel is the lead coordinator for the Dairy Products and Processing Technologies group at the Center for Dairy Research at the University of Wisconsin – Madison. Before joining CDR, Daniel worked as an analytical chemist developing methods for the infant formula industry prior to earning a PhD at the University of Wisconsin – Madison in Food Science where he investigated the use of membrane filtration to develop novel dairy products for use in beverages and high protein yogurts.

Innovative Flavors and Product Contests:

This competition offers the opportunity for ice cream and frozen dessert makers as well as dairy processors and flavoring supplies, to showcase their latest ice cream flavors, novelties and cultured dairy products (cultured milk, yogurt, sour cream, cottage cheese and dips) and flavors.

All conference attendees are invited to submit one entry to compete in each of the following categories:

- Most Innovative Ice Cream Flavor

- Most Innovative Ice Cream Novelty

- Most Innovative Prototype Ice Cream Flavor

- Most Innovative Culture Dairy Product

- Most Innovative Cultured Dairy Prototype Flavor

Awards will be given for first-, second- and third-place winners in each of the Ice Cream categories, judged by conference attendees. An award will be given for first place winners in the Cultured Dairy Products, judged by conference attendees. All winners will be featured in an upcoming edition of Dairy Foods magazine.

To submit an entry, complete the contest entry form no later than Friday, March 13th. Please contact vpender@idfa.org any questions.

Sponsored by:

Guidelines for Contest Submissions

-

- A company representative must register for the Ice Cream & Cultured Innovation Conference to participate.

- Limit of one (1) entry per company, per category.

- Please plan for your product submission to arrive between April 10 and April 13. If your product is received after April 13, we cannot guarantee that your entry will be included in the contest.

- Please send product according to the below requirements per category:

Ice Cream Flavors and Novelties:

NEW THIS YEAR: Participating companies will be sent a standard container (plus one spare in case of any damage) to send their contest entry in, along with a label that must be used for shipping to the hotel.

For ice cream novelties, please send at least thirty-six (36) pieces for each entry. Novelties should use plain wrappers, if possible. The lid or the outside of the novelty box MUST have the company name and the flavor.

Cultured Milk, Yogurt, Sour Cream, Cottage Cheese and Dips:

NEW THIS YEAR: Participating companies will be sent a label that must be used for shipping to the hotel.

Please send enough product so that 200 individuals may sample the submission. For example, if your product is a 6-10 oz. container, send 40 containers; if it is a 16-32 oz. container, send 20 containers.

If the cultured dairy product is submitted in the original retail containers, the product will be placed in individual portion cups for the contest.

- Be sure to pack the shipment well, wrapping each container in bubble wrap or paper to help protect it from damage during the extreme cold temperature of the dry ice.

- The box MUST be clearly marked as follows:

Ice Cream Flavors and Novelties:

"Must Be Kept Frozen" and "IDFA Ice Cream Contest".

Cultured Milk, Yogurt, Sour Cream, Cottage Cheese and Dips:

"Must Be Refrigerated" and "IDFA Product Contest".

- A shipping label will be provided – Please complete and attach the label to your shipped box(es).

- Once the product is shipped, email vpender@idfa.org with the information below. If you do not email the required information, we cannot guarantee that your entry will be included in the contest.

- Tracking number(s)

- Arrival date

- Number of boxes and approximate size and weight of shipment

- Submission name and product type

- Company contact attending the conference

Hotel

The Ritz-Carlton Naples, Tiburón

You may make your hotel reservations online or directly with the hotel by calling 877-557-3092. When calling, please refer to the IDFA Ice Cream & Cultured Innovation Conference to receive the special rate of $359 per night plus applicable taxes. The deadline to secure a room is March 23, 2026 or until the room block sells out. We have reserved a large block of rooms, but once the room block is full, we cannot guarantee that additional space will be available.

Hotel reservations can be canceled up to seventy-two (72) hours prior to arrival without fees. If complete cancelation on an individual reservation takes place within seventy-two (72) hours of the scheduled arrival a cancellation fee equal to one (1) night room and tax will be charged by the hotel.

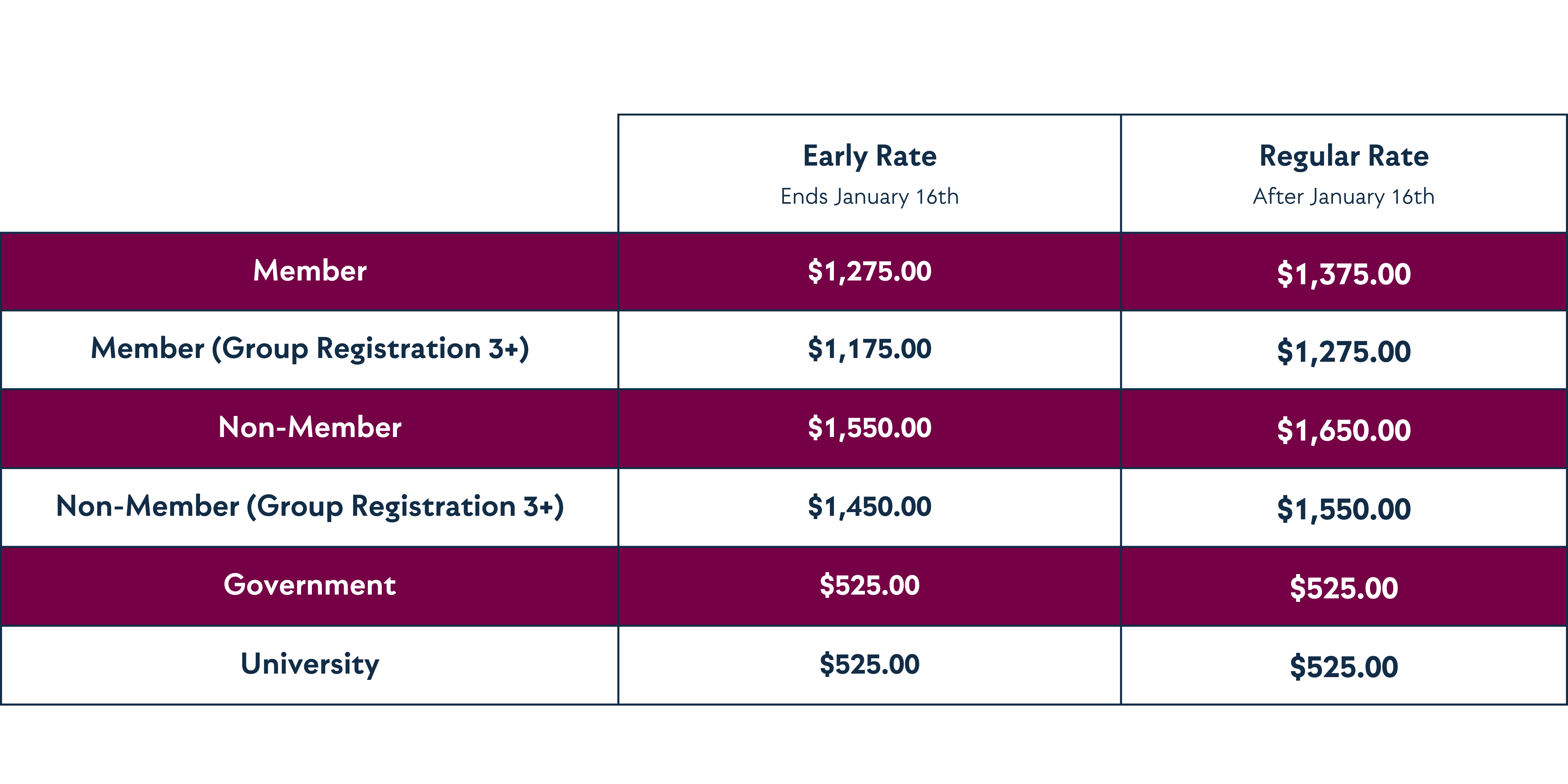

Registration:

Registration fees are based on your company’s IDFA membership status. For more information about membership, please email membership@idfa.org.

Registration will open on November 17.

Q: Registration Substitutions

Registration is non-transferable from one company to another; however, substitutions within companies are welcome at any time. Please email registrar@idfa.org if you would like to make a registration substitution.

Q: Registration Cancellation Policy

Registration cancellations received in writing will be accepted prior to March 17, 2026 for a full refund, minus a $75 processing fee. Cancellations received after March 17, 2026, will be eligible for a 50 percent refund, less the processing fee. Your registration fee is non-refundable after March 18, 2026. Substitutions may be made without penalty. All cancellations and substitutions must be received in writing at registrar@idfa.org.

Q: News Media

Credentialed members of the news media are welcome to register at a special rate by contacting ajerome@idfa.org. News media must present credentials to qualify.

Questions: If you have questions or need assistance with the registration process, please contact IDFA at (202) 737-4332 or registrar@idfa.org.

Sponsorships:

The Ice Cream & Cultured Innovation Conference delivers high value and an opportunity to engage with more top-level decision makers than ever before — including executives, plant managers, regulatory compliance personnel, product development specialists, research and development professionals, quality assurance staff, plant engineers, and operations personnel.

Sponsorship is one of the best ways to brand your organization as a thought-leader and to highlight your commitment to advancing the dairy industry. IDFA offers a variety of sponsorship opportunities.

Please contact lgold@idfa.org for more information.